In today's world of electronic products, the technological innovation of electronic components continues to improve, the pace of innovation continues to move forward, if as a good electronic components suppliers do not follow the pace of innovation, do not pay close attention to the electronic components innovation trends, then there is a risk of being eliminated from the industry. Among them, the electronic components in the connector and relay more obvious. That how to understand the direction of technological innovation in connectors and relays?

Connector technology innovation direction: small pitch, high density, high frequency

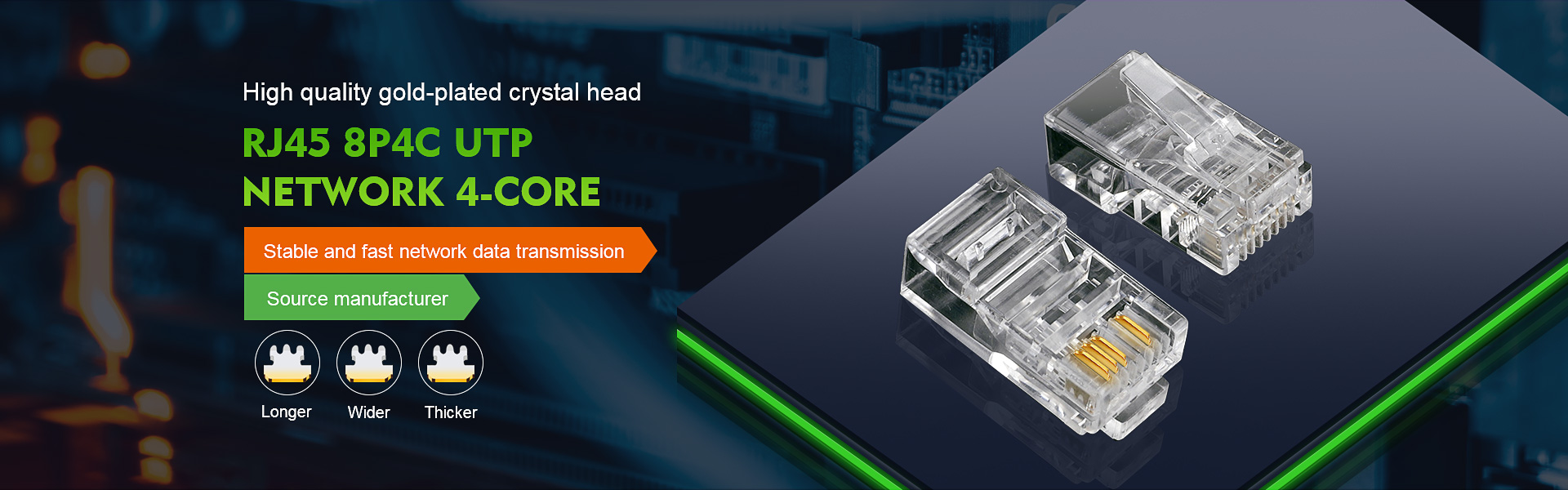

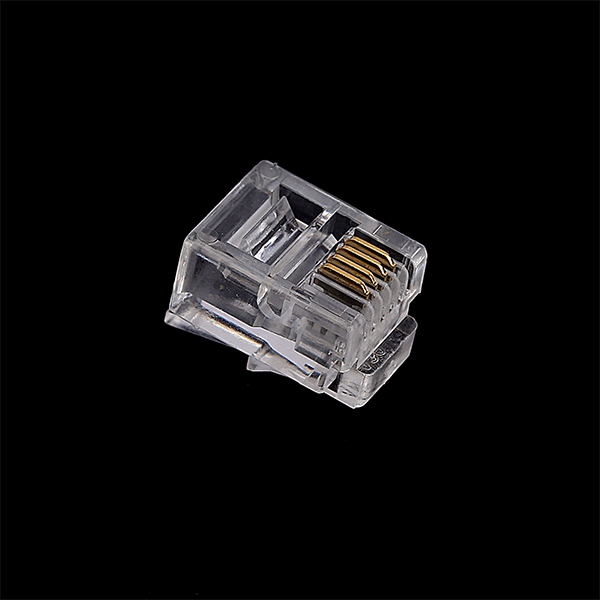

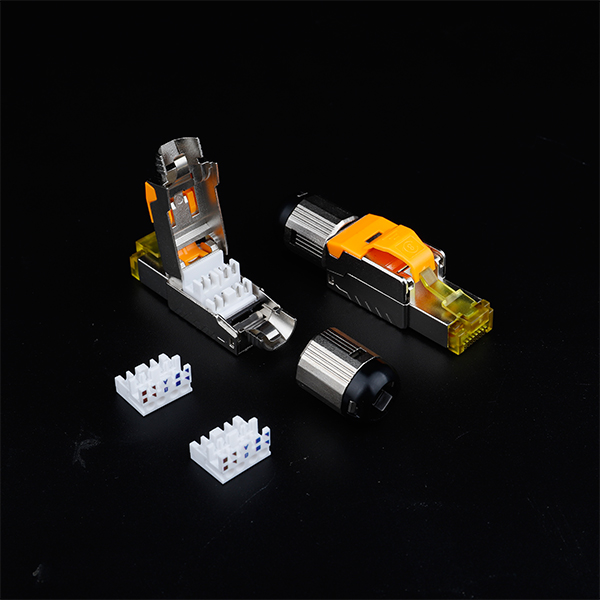

Connector development should be miniaturized, high density, high-speed transmission, high-frequency direction. Miniaturization refers to the connector center spacing is smaller, high density is to achieve a large number of cores. High-density PCB (printed circuit board) connector effective contact pieces totaling 600 cores, special devices up to 5000 cores. High-speed transmission refers to modern computers, information technology and networking technology requires signal transmission time scale rate up to the megahertz band, pulse time to reach sub-milliseconds, and therefore requires high-speed transmission connectors. High-frequency is to adapt to the development of millimeter-wave technology, RF coaxial connectors have entered the millimeter-wave operating frequency band.

Relay technology innovation direction: combination, high reliability, small size

Relays should continue to miniaturize and piecemeal in volume and form factor. Functionality should be developed from a single switch function of the traditional relay to combined relays, assembly technology should be SMT (surface mount) to micro assembly (MPT), microelectromechanical systems (MEMS) direction. General purpose relays should continue to develop in the direction of small size, thinness and plastic sealing. Low height, high sensitivity, and high reliability relays for printed circuit boards are still the mainstream products in the general purpose relay market. The reed relay market continues to expand, and products should be developed from open type to plastic sealed direction. High I/O insulation of plastic sealed reed relays is attracting attention. Solid state relays will become more widely used, and products should be developed in the direction of high reliability, small size, high resistance to inrush current impact and high anti-interference. Military relays should be developed in the direction of dual-use for military and civilian use. TO-5 relays and 1/2 crystal hood relays compatible with IC are still the focus of small sealed relay market development, but should be developed in the direction of high environmental adaptability and high reliability. There is still a market for multi-contact groups and large load dual-use relays.

- Connector manufacturers explain the motion controller technology using pin connectors more suitable for industrial

- Need to note the ten points of connector connector performance

- Electronic components in the connector and relay technology innovation direction

- Connector selection should pay attention to these fourteen criteria

Follow Sweep

Follow Sweep