In recent years, China's rapid development in the field of communications, mathematical communications and control circuit systems have also revealed a number of problems, mainly due to: poor contact caused by a high rate of error and lead to the entire system is not smooth, resulting in failure of the main reason for the quality of the connector is also the use of environmental issues, especially the quality of the gold plating layer is the greatest impact.

In the current situation of the continuous development of communication systems, the use of connectors is becoming more and more widespread, and the number of more and more. The electrical contact reliability of the connector directly affects the operation of the entire communications system, and the quality of the connector gold plating layer is one of the important parameters to evaluate the quality of the connector.

At present, the domestic production of the connector gold plating layer there are some quality problems, mainly in: uneven thickness of the gold plating layer, the number of micro-porous, wear-resistant plating and low corrosion resistance, etc., through the domestic and foreign production of the connector gold plating layer test analysis comparison, the domestic production of the connector gold plating layer quality needs to be improved.

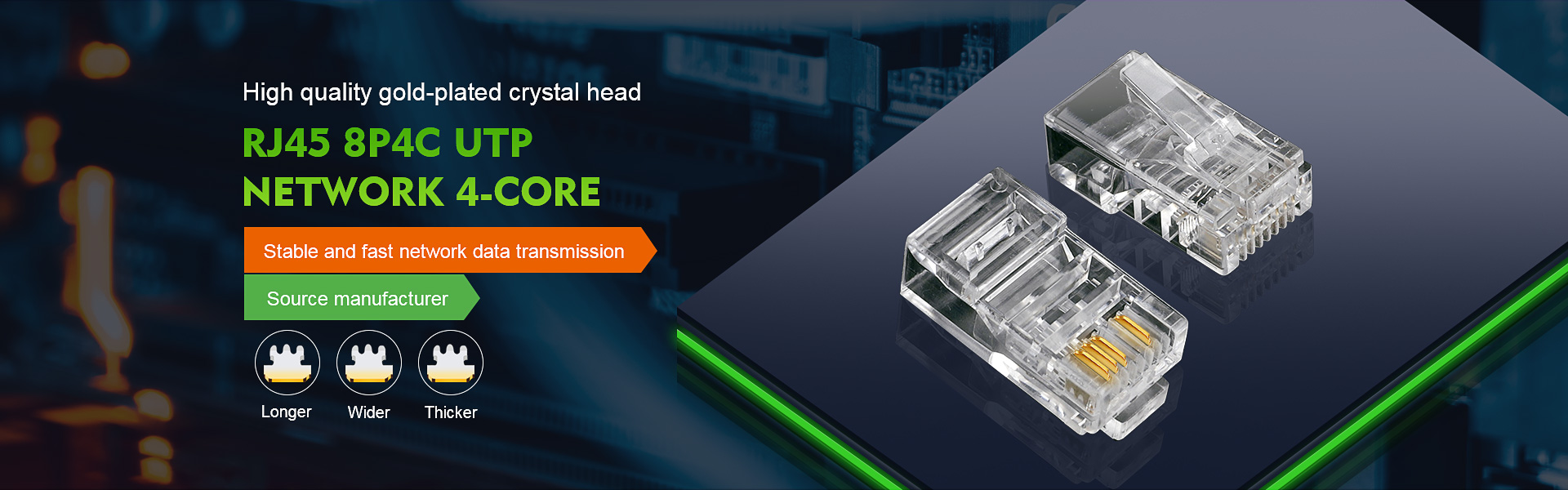

Connector substrate material is copper alloy, the surface coating is gold and its alloy, which is because all inert metal, in a variety of corrosive environments are not corroded, and low resistivity, and the substrate material has good adhesion, the protection of the substrate material is not corroded, to protect the connector good electrical properties. The disadvantage is that it is expensive, the plating layer is thin, so the microporosity problem is more prominent. Pure gold hardness is low, easy to bond, wear, the use of gold alloy for the plating layer to improve its hardness and wear resistance.

In addition, the base metal copper easy for the surface plating layer diffusion, when the copper diffusion to the surface, oxidation in the air to generate copper oxide film and lead to electrical contact failure, in order to prevent its occurrence, so in the base copper and surface gold plating layer between the nickel plating, and due to the existence of microporosity of gold plating layer, so that nickel exposure to the environment and with the atmosphere of sulfur dioxide (So2) reaction to generate nickel sulfate (Niso4﹒XH2O), the generation of insulation and the volume is corroded metal volume is much larger, so along the micro-hole spread to the gold plating layer, resulting in contact failure.

It can be seen that one of the key indicators to evaluate the quality of gold plating layer is the microporous rate of gold plating layer (the number of microporous per square centimeter area), and the microporous rate and the thickness of the plating layer has a close relationship, the thicker the plating layer, the lower the microporous. If the plating is too book, there are a large number of microporous presence, the base metal is exposed to the environment, the plating not only does not play a proper protective role, but also because of gold and the substrate material (nickel or copper alloy) between the potential difference is very large, thereby accelerating electrochemical corrosion, while the substrate surface roughness and microporous rate has a close relationship, the lower the surface roughness, the lower the microporous rate.

Connector plugging life by its ability to resist wear and tear, such as gold plating is worn so that in the bottom exposed, the substrate may be corroded, and its generation will lead to electrical connection failure. So far, the connector has developed into a full range of products, a rich variety of specifications, a variety of structural types, professional direction subdivision, industry features, standard system standardized series and specialized products, how to evaluate the quality of the connector gold plating layer key indicators have become an important indicator of the connector industry professionals to measure the quality of the connector.

- What are the common terminology used in connectors?

- Customers should be concerned about those points when choosing a connector?

- Connector manufacturers in-depth analysis of the key indicators of the quality of the connector gold plating layer

- High-speed electrical connectors in the development of the four characteristics and the use of three key technologies

Follow Sweep

Follow Sweep